-

Company

-

Products

-

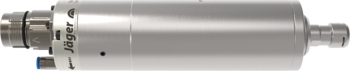

Z-Line

Z-Line

- Highest precision, stability, and running smoothness

- Rated power up to 10 kW

- Rated rotation speed up to 100.000 U/min

-

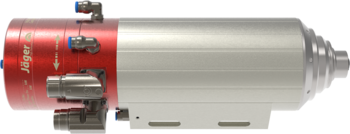

F-Line

F-Line

- Customized flange types

- Rated power up to 67 kW

- Rated rotation speed up to 50.000 rpm

-

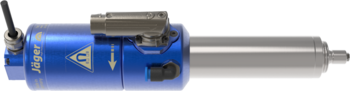

ARS-Line

ARS-Line

- Dressing grinding wheels

- Higher precision

- Accurate grinding

- Cut detection

-

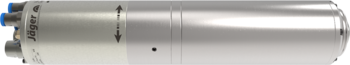

Block-Line

Block-Line

- Individually manufactured block housing

- Various clamping systems

- Rated rotation speed up to 60.000 rpm

-

Chopper

Chopper

- Various clamping systems in one basic body

- Rated power up to 6,5 kW

- Rated rotation speed up to 40.000 rpm

-

DentaDrive

DentaDrive

- Modular unit assembly system

- Individually configurable

- Rated power up to 0,31 kW

- Rated rotation speed up to 100.000 rpm

-

Power-Line

Power-Line

- More output with the same housing diameter

- Rated power up to 3,7 kW

- Rated rotation speed up to 80.000 rpm

-

Z-Line

-

Motors

- Service

-

Careers

- Currently

- Contact Us